Tips for Scratch-Free CNC Machining of Precision Aluminum Parts include: Choose the appropriate cutting tools and cutting parameters. Suitable tools and cutting parameters should be selected based on the material, shape, and machining requirements of the aluminum parts to ensure optimal cutting performance. Keep the equipment clean and well-maintained. CNC machining equipment should be cleaned and inspected […]

CNC machining aluminum is a popular manufacturing process used in various industries. This process involves the use of computer-controlled machines to remove material from a solid block of aluminum to create a desired shape or design. One of the benefits of CNC machining aluminum is its high precision and accuracy. The use of computer-controlled machines ensures that […]

CNC machining copper is a highly precise and efficient method of producing complex parts and components. Copper is a versatile material that is widely used in various industries, including electronics, aerospace, and automotive. With CNC machining, copper can be shaped into intricate designs with high accuracy and repeatability. One of the main advantages of CNC machining […]

Die casting is a manufacturing process used to create metal parts by forcing molten metal into a mold cavity. This process is known for its high efficiency, accuracy, and durability. In this article, we will explore the process and advantages of die casting. One of the main advantages of die casting is its ability to […]

Injection molding is a versatile process compatible with a wide range of materials since it is ideal for merging two different components into one product exterior or top layer in insert molding. Thermoplastic and thermoset materials are primarily used in injection molding due to their strength, sturdiness, or good electricity flow. Thermoplastics: Polypropylene (PP), Nylons (Polyamides/PA), polycarbonate […]

Aluminum is a primary metal in die casting, which in alloys is utilized for the cold-chamber die casting process. These aluminum alloys typically comprise elements such as magnesium, copper, and silicon. Aluminum-based die casting alloys are a superb choice for intricate, finely detailed pieces as they are lightweight and provide excellent dimensional stability. They have […]

CNC machining involves the use of computer software to control the movement of machines and tools. The process starts with a CAD (Computer-Aided Design) model, which is then translated into a CNC program that controls the movement of the machine. The machine then cuts, drills, or shapes the material according to the program’s instructions.

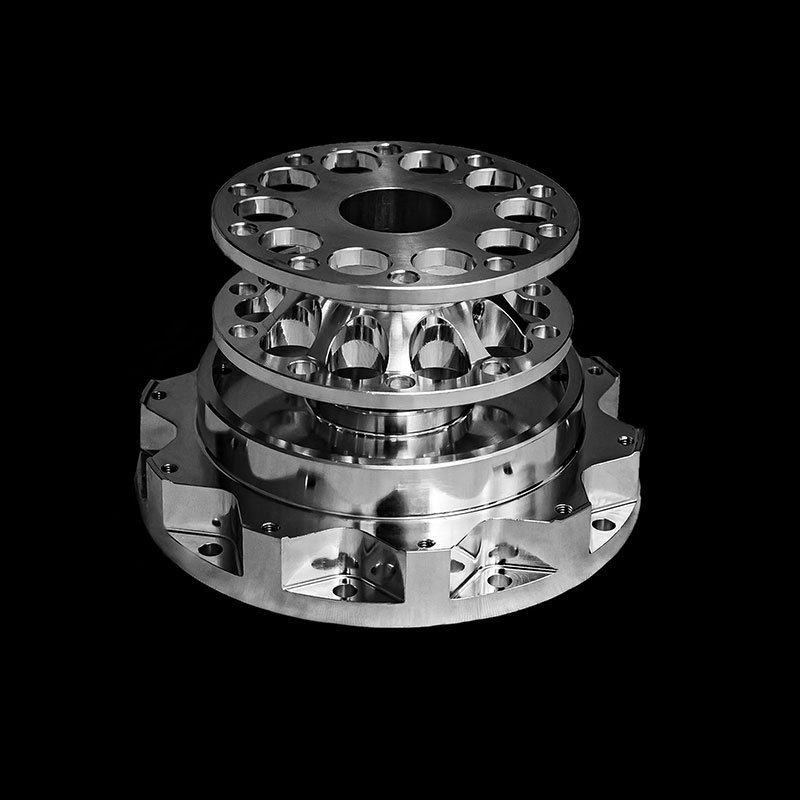

The manufacturing industry has undergone an immense transformation since the inception of CNC machining. The introduction of high precision CNC machining has taken the industry to another level. The use of Computer Numerical Control (CNC) systems has revolutionized the way products are manufactured. CNC machining has made it possible to manufacture complex parts with high […]

5 Axis CNC machining has revolutionized the manufacturing industry, allowing for complex and intricate designs to be produced with precision and accuracy. With the ability to manipulate the cutting tool in five different axes, manufacturers can create parts with more intricate shapes and contours than ever before. One of the main advantages of 5 Axis CNC […]

CNC machining prototype is a process that involves the use of computer-controlled machines to create precise and accurate parts. This method is widely used in various industries, including aerospace, automotive, and medical. One of the advantages of CNC machining prototype is its high level of accuracy. With computer-controlled machines, the parts produced are consistently precise, ensuring that […]