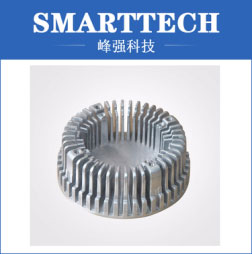

Stainless Steel Die Casting Parts

Stainless Steel Die Casting Parts,Casting is a manufacturing process by which a liquid material is usually poured into a mold, which contains a hollow cavity of the desired shape, and then allowed to solidify.

Stainless Steel Die Casting Parts

Casting is a manufacturing process by which a liquid material is usually poured into a mold, which contains a hollow cavity of the desired shape, and then allowed to solidify. The solidified part is also known as a casting, which is ejected or broken out of the mold to complete the process.

Sand casting, also known as sand molded casting, is a metal casting process characterized by using sand as the mold material.

It is relatively cheap and sufficiently refractory even for steel foundry use. A suitable bonding agent (usually clay) is mixed or occurs with the sand. The mixture is moistened with water to develop strength and plasticity of the clay and to make the aggregate suitable for molding. The term “sand casting” can also refer to a casting produced via the sand casting process.

Stainless Steel Die Casting Parts

There are six steps in this process:

1 Place a pattern in sand to create a mold.

2 Incorporate the pattern and sand in a gating system.

3 Remove the pattern.

4 Fill the mold cavity with molten metal.

5 Allow the metal to cool.

6 Break away the sand mold and remove the casting.

If you want to get more die casting mould information,please visit to http://www.smartmoldtech.cn or mail to david.wang@smartmoldtech.com. Welcome send us drawings or samples, we will quote the best price and give professional advices. We can also design drawings for customers upon required informaiton. Thanks !