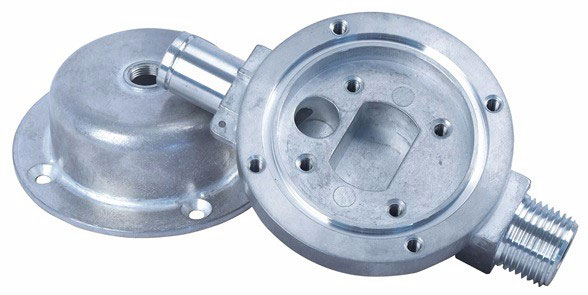

Die casting clamp handle lever

Metal parts for vehicle, agriculture machine, construction machine, transportation equipment, Valve and Pump system.In a word,die casting clamp handle lever is very versatile.

- General Details

Die casting clamp handle lever

General Products Application /Service Area:

Metal parts for vehicle, agriculture machine, construction machine, transportation equipment, Valve and Pump system. E.g. Engine bracket, truck chassis bracket, gear box , gear housing , gear cover, shaft, spline shaft , pulley, flange, connection pipe, pipe, hydraulic valve, valve housing ,Fitting , flange, wheel, flywheel, oil pump housing, starter housing, coolant pump housing, transmission shaft , transmission gear, sprocket, chains etc. In a word,die casting clamp handle lever is very versatile.

die casting clamp handle lever

Product Name Best Selling Auto Products Zinc And Aluminum Die Casting Main blank Process for Aluminum Casting Die Casting, Permanent Molding /Gravity Casting, Low Pressure Casting,

High Pressure Casting/Sand Casting, Extrusion Casting etc.Blanks Tolerance -Casting Tolerance CT4-6 for Permanent Molding, Die Casting. CT 9-11 for Sand Casting Applicable Material for zamak casting Zn Alloy Zamak 3, Zamak 5, Zamak 7, Zamak 2, A356.0/ZL101,GAlSi7Mg (3.2371.61)/AlSi7Mg/, A-S7G, Al Si Alloy, Al Cu Alloy ZL201 Al Mg Alloy ZL301,ZL302, Al Zn Alloy ZL401Or according to customer requirements Casting Blank Size /Dimensions 2 mm-1500mm / 0.08inch-60inch , or according to customer requirements Applicable Machining Process CNC Machining/ Lathing/ Milling/ Turning/ Boring/ Drilling/ Tapping/ Broaching/Reaming /Grinding/Honing and etc. Machining Tolerance From 0.005mm-0.01mm-0.1mm Machined Surface Quality Ra 0.8-Ra3.2 according to customer requirement Applicable Heat Treatment T5~T6 Applicable Finish Surface Treatment Shot/sand blast, polishing, Primer Painting , Powder coating, ED- Coating,

Finish Painting, Anodize (White or Black Color), as customers request.MOQ per batch For casting parts: 100pcs For Machining parts: 50pcs Lead Time about 50 days for zinc and aluminium die casting

die casting clamp handle lever

Packing & Delivery (Show As Above):

Inner Packing →Strong & waterproof plastic big is packed inside, to keep the product in safe condition.Or as customer requests.

Outer Packing →Multilayer wooden box with strong bandages, used for standard export package. Or customized as per customer’s requirements.

If you want to get more die casting mould information,please visit to http://www.smartmoldtech.cn .

- Comments

- Related Products