Main categories of plastic mould

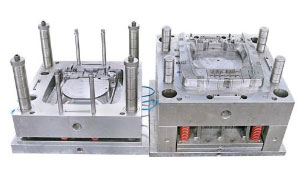

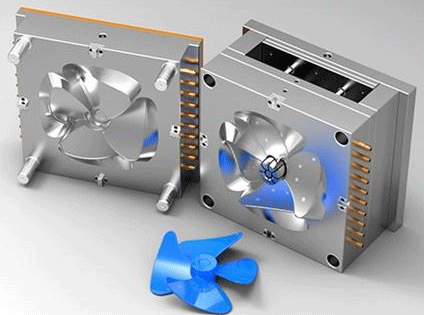

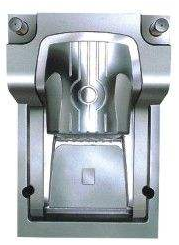

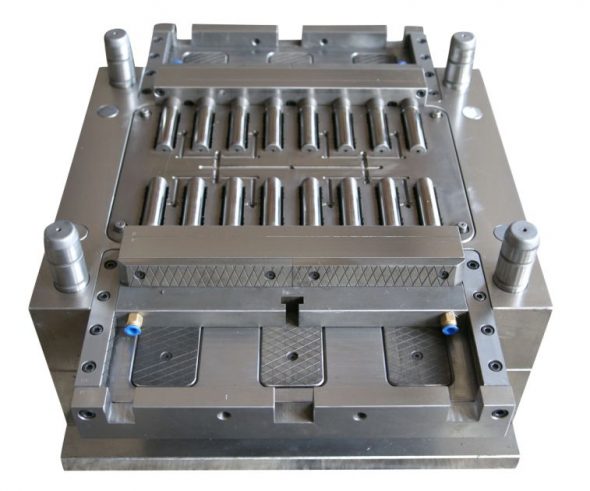

Main categories of plastic mould According to the different molding methods, can be divided into different types of plastic processing mold corresponding to different process requirements, mainly plastic injection mould, plastic pressing mould, plastic extrusion mould, plastic blow mould, blister molding mould, high foam polystyrene molding mould. Smart Mold Technology Ltd. is one of the […]