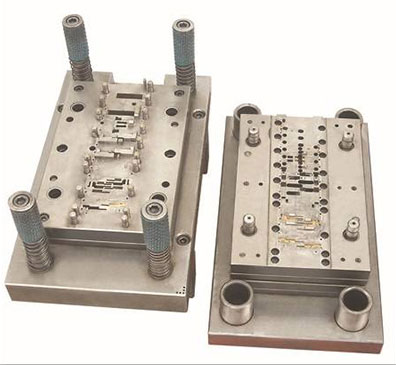

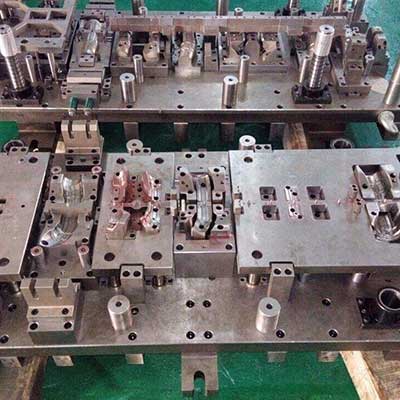

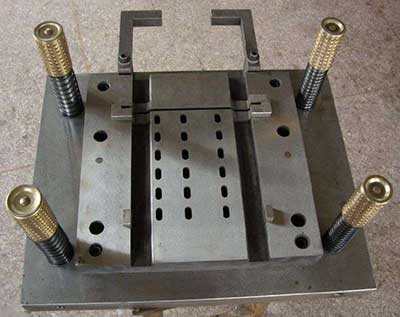

Extrusion mould

Extrusion mould A pressure machining method in which the blank placed in the die is pressurized by a punch or punch to produce a plastic flow, thereby obtaining a workpiece corresponding to the mold hole or the shape of a concave punch.During extrusion, the blank is subjected to three – way compressive stress. Smart Mold […]